plastic Pelletizer Machine For Sale Nigeria

Brand: Shuliy

Factory History: 12 years

Exporting countries: 60+

Function: used to remelt waste plastics, then extrude plastic strips and cut them into recycled plastic pellets.

Common Raw Materials: PP plastics, PE plastics, LDPE plastics, HDPE plastics, EPS foam, EPE foam, etc (customized capacity available) ;

Output capacity: 100kg to 500kg per hour (customized capacity available)

Screw Diameter: 105mm-220mm

Color: customized available

Choose Reliable Plastic Granulator Manufacturers For Nigerian

Factory And Certificate Show

240+Global Cases Show

What kind of waste plastic can be processed?

What Kind Of Plastic Pellets Will You Get?

How much profit will you make?

| 500kg/hour pp plastic granulation line cost analysis | |||||

| Raw material | Basic Data | 500kg/hr | 22.5Hours | 4 yuan/kg | |

| Electricity bill | Basic Data | 400KW/H | 22.5Hours | 0.725/KWH | |

| Manpower | Basic Data | 4 people/class | 2 shifts/day | 100/person/day | |

| Particles | Basic Data | 475kg/hr | 22.5Hours | 5.8/kg | |

| Daily input | |||||

| Project | Unit | Consumption | Unit price | Total Remark | |

| Raw material | kg | 11250 | ¥4.00 | ¥45,000.00 | |

| Electricity bill | KWH | 8100 | ¥0.73 | ¥5,872.50 | |

| Manpower | Person | 8 | ¥100.00 | ¥800.00 | |

| Total | ¥51,672.50 | ||||

| Daily output | |||||

| Project | Unit | Quantity | Unit price | Total Remark | |

| Plastic particles | Pieces | 10687.5 | ¥5.80 | ¥61,987.50 | |

| Total | ¥61,987.50 | ||||

| Profit | |||||

| Daily Profit=61987.5-51672.5=10,315.00 | |||||

| Month Profits (30 days)=309450 | |||||

| Annual (12 Months)=3713400 | |||||

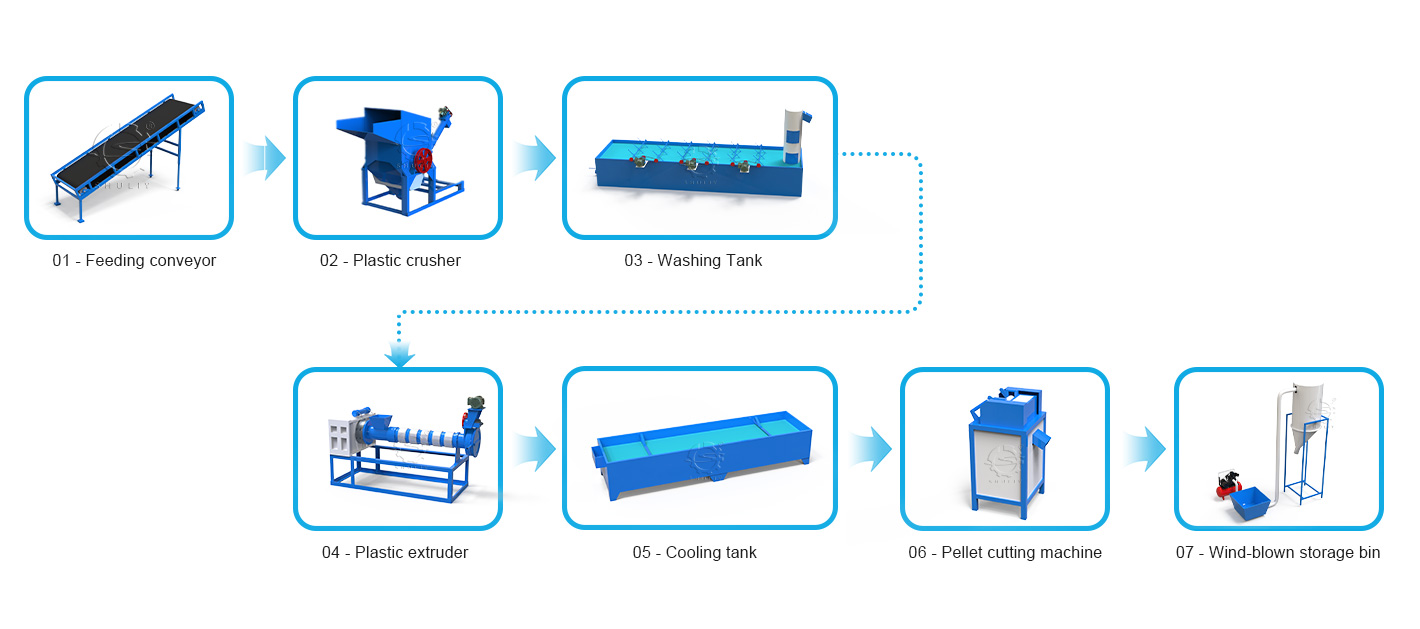

What is the production process of the plastic granulator For Sale Nigeria?

Waste plastic pretreatment

- Waste plastic transportation: The raw materials are transported to the crusher through the belt conveyor for crushing and cleaning.

- Waste plastic crushing: Waste plastic is broken into small pieces by plastic crusher, and then enters the cleaning tank through a conveyor for cleaning and sedimentation of impurities

- Drying of wet plastic pieces: dryer machine dehydrates the broken plastic coming out of the pool

Melt extrusion

- Melting: Use a screw melting machine to melt the plastic through high temperature, high pressure and stirring.

- Filter screen: The melted plastic solution needs to filter out impurities and foreign matter through the filter screen to ensure the quality of the particles.

- Extrusion: Compress the molten plastic solution and extrude plastic strips

- Cooling: The heated and filtered plastic solution needs to be cooled into granules. We can use water cooling for rapid cooling.

Plastic cutting

Plastic cutting: the cooled plastic block is cut into particles of a certain size by a cutting machine. The particle size can be adjusted according to your requirements.

Screening and packing

Plastic granule packaging machine: Screen the granules, remove unqualified granules, and then pack and store them.

What are the advantages of plastic granulator For Sale Nigeria?

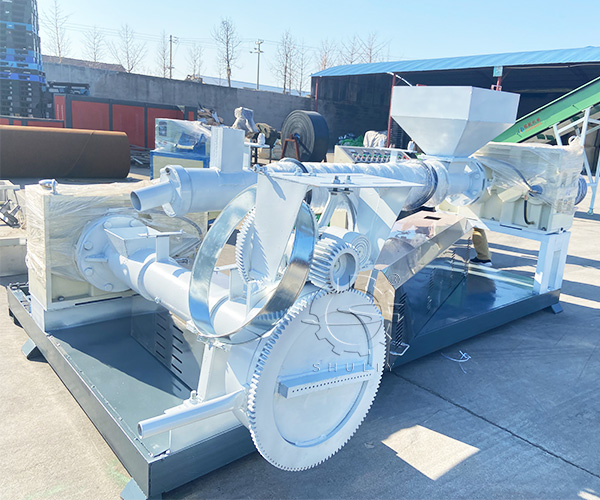

High-quality material

The screw of Shuliy plastic granulator is made of 40 CR medium carbon alloy steel material, which can maintain stability under high temperature, high pressure and high speed operation.

High work efficiency

The control cabinet is fully controlled, with a high degree of automation, simple and convenient operation, and high production efficiency, which can greatly improve production efficiency and reduce labor costs.

Long Service life

The components of the plastic granulator are made of high-quality materials, which are durable and can work stably for a long time. Our old customers have machines that have been used for more than 10 years, and they are still running well.

Easy to install

Our plastic granulator has been installed before leaving the factory and shipped as a package. Usually do not need too much commissioning and installation work, and can be put into operation quickly

High quality

Parts and components have been precision processed and high-quality testing, which can ensure the stable quality of particles and reduce the occurrence of defective products.

Energy saving

The use of high-efficiency motors and heat exchangers can minimize energy waste, improve production efficiency and reduce production costs.

Reasonable layout

The layout is reasonable, the structure is compact, and the space occupied is small, which can save the workshop space to the greatest extent.

Run smoothly

Using advanced control system, it can automatically adjust production parameters to ensure production stability and consistency.

What kind of services does Shuliy Group provide?

One-stop customized service

We can customize production plans and production lines, and issue layout drawings according to customer needs to ensure that customers can get satisfactory solutions.

One-to-one service

We are customer-centric, responsible for the whole process, and update the production and delivery progress for customers at any time to meet customer needs.

After-sale guarantee

We support online or offline on-site installation, provide after-sales document support (operation manual, maintenance manual), and provide online customer service to solve problems at any time. In addition, we also provide online training and regular telephone return visits to ensure that customers can receive timely help and support.