Shuliy continuous carbonization furnace is a new type of carbonization furnace. It has the characteristics of high return, low investment, and wide application, and is favored by the majority of customers. We have focused on carbonization furnace design for about 20 years and can provide the best charcoal machine at a reasonable price. Please learn more about us if you want to start an investment in the charcoal manufacturing business.

get a free quote

5000+ Biochar Production Equipment Cases Display

Shuliy Group specializes in the development and manufacture of charcoal manufacturing machines. Our charcoal maker machine has been successfully exported to more than 50 countries such as the Philippines, Malaysia, Japan, Myanmar, Iraq, Congo, Uganda, Romania, the United Kingdom, etc. All biomass pyrolysis plants installed so far are operating well. Through after-sales tracking feedback, we learned that customers have gained huge benefits from carbonization projects.

Choose Right Continuous Carbonization Furnace Model

The production capacity of the Shuliy carbonizer machine varies from 500kg/h to 3000kg/h. Here we show the newest model of carboniser. But if you would like a machine with other capacities, we can provide you with another model or offer you a tailor-made solution.

| Item | Model | |||

| Model | SL-JH-0812 | SL-JH-1015 | SL-JH-1218 | SL-JH-1320 |

| Hourly Feeding Capacity | 500kg | 0.8-1 Tons | 1.5-2Tons | 2.5-3Tons |

| Working Method | Continuous Carbonizing | |||

| Reactor Size | Φ800mm | Φ1000mm | Φ1300mm | Φ1700mm |

| Heating Materials | Charcoal, wood, diesel, natural gas, LPG, biomass pellets, etc. | |||

| Total Power | 40kw/h | 55kw/h | 60kw/h | 72kw/h |

| Floor Area (L*W*H) | 30m*15m*7m | 35*15*7m | 45*15*10m | 50*15*10m |

| Operating Pressure | Constant Pressure | |||

| Cooling Method | Recycling Water Cooling | |||

| Life Span | 5-8 Years |

Raw Materials You Can Process

Note: many Shuliy carbonization equipment using coconut shells, wood, palm kernel shell, jute stick, bamboo, wheat straw, etc. as raw materials are sold well in Indonesia, Vietnam, Malaysia, the Philippines, Romania, France, Germany, the United Kingdom, Poland, Oman, Yemen, Iran, and other countries.

What You Will Get From Biochar Machine

Our charcoal machines’ price starts at $50,000. But the charcoal yield is about 3:1. And the main end product we get is artificial carbon with a fixed high carbon content (about 90%). This shows that you will get huge profits. In addition, you can also get tar, wood vinegar, and combustible gases during the carbonization process. Below are the uses of each product.

Note: Activated charcoal cannot be obtained from our machine.

Charcoal:

Wood Vinegar:

Wood Tar:

Flammable gas:

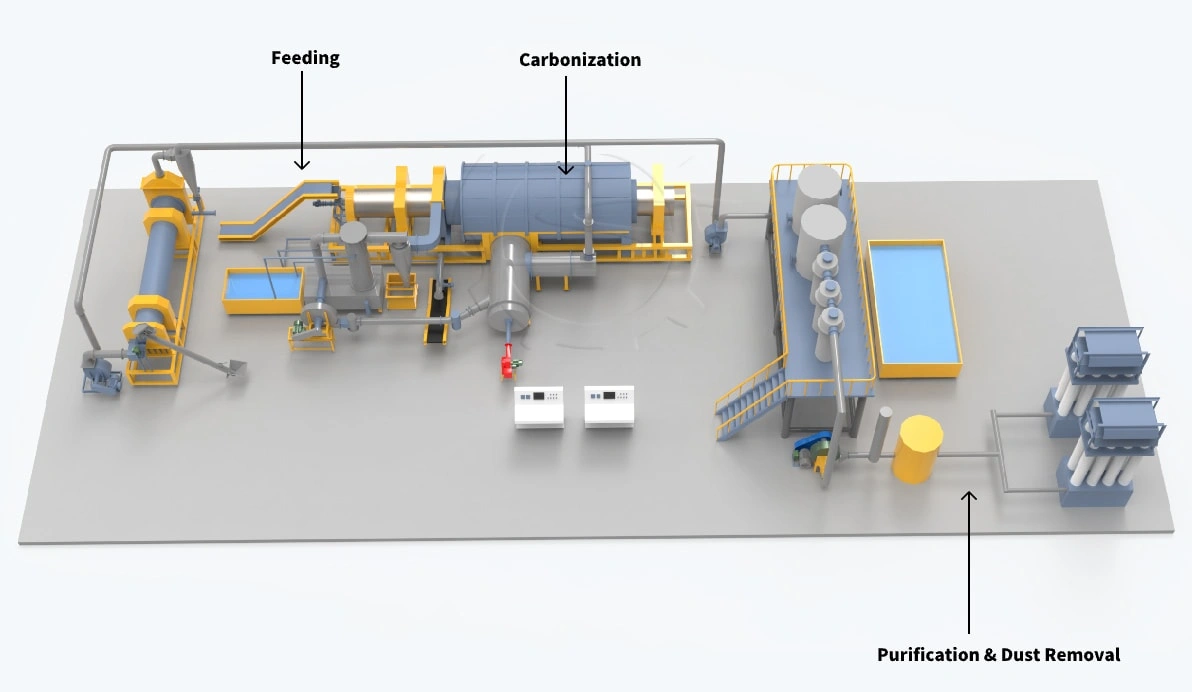

Production Process You Want Know

Product Advantage You Want to Know

Modular Design

Adopt flexible heat utilization

Introduce advanced automation technology

Why Choose Shuliy Charcoal Furnace?

Shuliy is committed to providing customers with high-quality charcoal furnace. Our equipment is not only of reliable quality and affordable price but also has a high customer order rate.