Brand: Shuliy

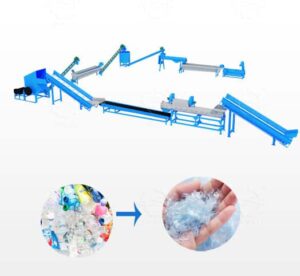

PP PE Plastic Film Recycling Line:polypropylene (PP) and polyethylene (PE). Disposable plastic products such as plastic bags, packaging films, agricultural films, etc.

HDPE/PP Hard Plastic Recycling Line:Plastic buckets, plastic benches, plastic basins, home appliance casings, pipes, plastic baskets, etc

Capacity: 100kg/h, 200kg/h, 300kg/h, 500-800kg/h,1-5t/h..

Particle Length: 4mm(conventional), can be customized.

Particle Diameter: 3mm(conventional), can be customized.

Warranty: 1 year.

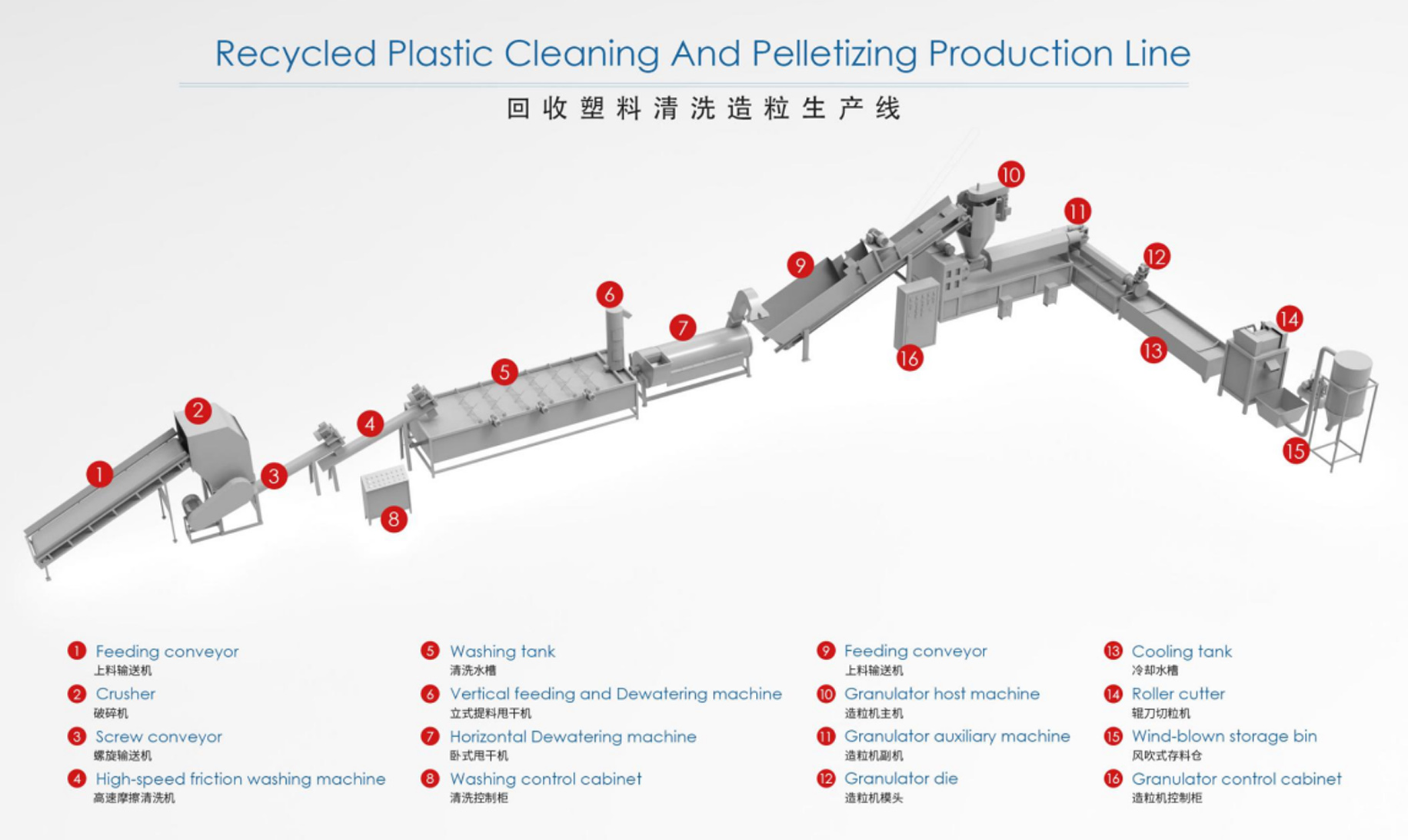

Function:Waste plastic recycling processed into recycled plastic pellets ( crushing, washing , rinsing tank, dewatering, cooling tank and pelletizing).

Advantage:Energy saving, modular design, simple operation.14+years of R&D experience, high cost performance, fast delivery, automation, less labor, low energy consumption, high efficiency.

Service: Free one-stop customized solutions. Installation and commissioning. Free training operation. Free design of factory installation drawings, welcome to visit our factory.

Plastic Recycling Equipments

Shuliy Group has provided plastic recycling machines for more than 20 years. Now please choose the most suitable plastic recycling line here according to your plastic material.

It is mainly used to process waste plastic film (industrial packaging film, agricultural plastic film, greenhouse film, handbags, etc.), woven bags, agricultural convenient bags, basins, barrels, beverage bottles, furniture, daily necessities, etc. It is suitable for the most common waste plastics. It is a widely used and popular plastic recycling machine in the waste plastic recycling industry.

Plastic Bottle Recycling Machine is mainly composed of crushers, cleaning tanks, dryers, plastic granulators and other equipment. The whole set of equipment has a high degree of automation. Only one employee is needed to operate the whole process, saving labor costs.

With special double-stage screw design and different configurations, it is suitable for the production of PET, PP, PE, PS, ABS, PA, PVC, PC, POM, EVA, LCP, PMMA and other plastic recycling granulation. The reduction box adopts the design of high torque, which realizes the performance of noiseless and smooth operation. The screw and barrel are specially hardened, which has the characteristics of wear resistance, good mixing performance and high output. The design of vacuum exhaust or ordinary exhaust port can discharge moisture and waste gas during the production process, so that the material can be discharged. It is more stable and the colloidal particles are stronger, which ensures the good quality of the product.

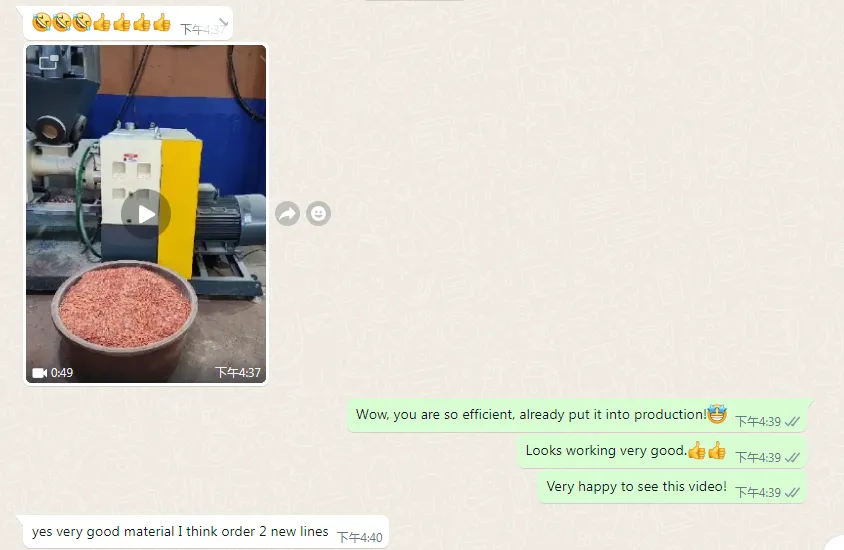

The plastic granulation production line has low energy consumption and high production efficiency. The recycled plastic particles produced have a smooth surface and uniform size, which can meet market standards.

Principle: Use the process of high-temperature melting, plasticization and extrusion to change the physical properties of plastics and realize plastic molding of plastics.

Wide range of applications: Easily process various hard and soft film plastics, suitable for factories of all sizes.

100kg/h, 200kg/h, 300kg/h, 500-800kg/h,1-5t/h.., precise automatic feeder, two alternative heating efficient methods, electromagnetic heating ring, ceramic heating, certified reducer. All of Shuliy’s recycling lines, including the PET production line, use certified hard-toothed reducers with high transmission efficiency, low noise, long service life and stable production.

Raw materials of Plastic Waste Recycling And Pelletizing Line

Final Product

What kind of services does Shuliy Group provide?

One-stop customized service

We can customize production plans and production lines, and issue layout drawings according to customer needs to ensure that customers can get satisfactory solutions.

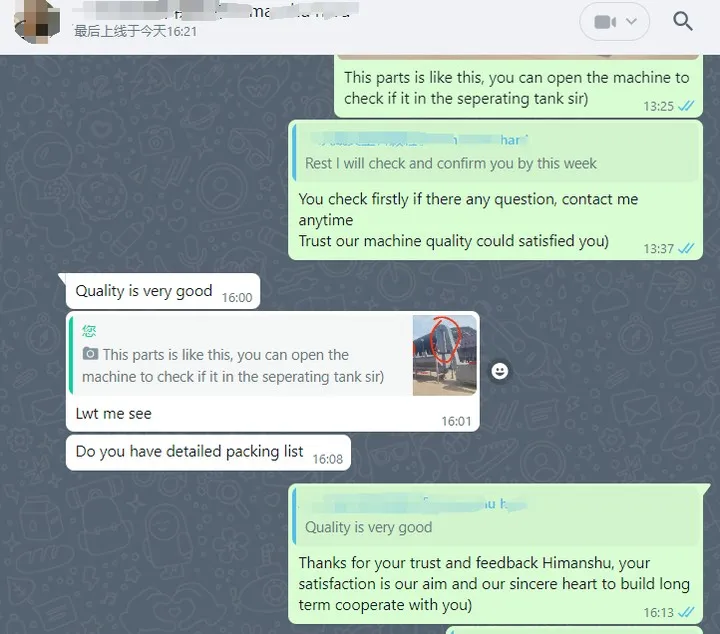

One-to-one service

We are customer-centric, responsible for the whole process, and update the production and delivery progress for customers at any time to meet customer needs.

After-sale guarantee

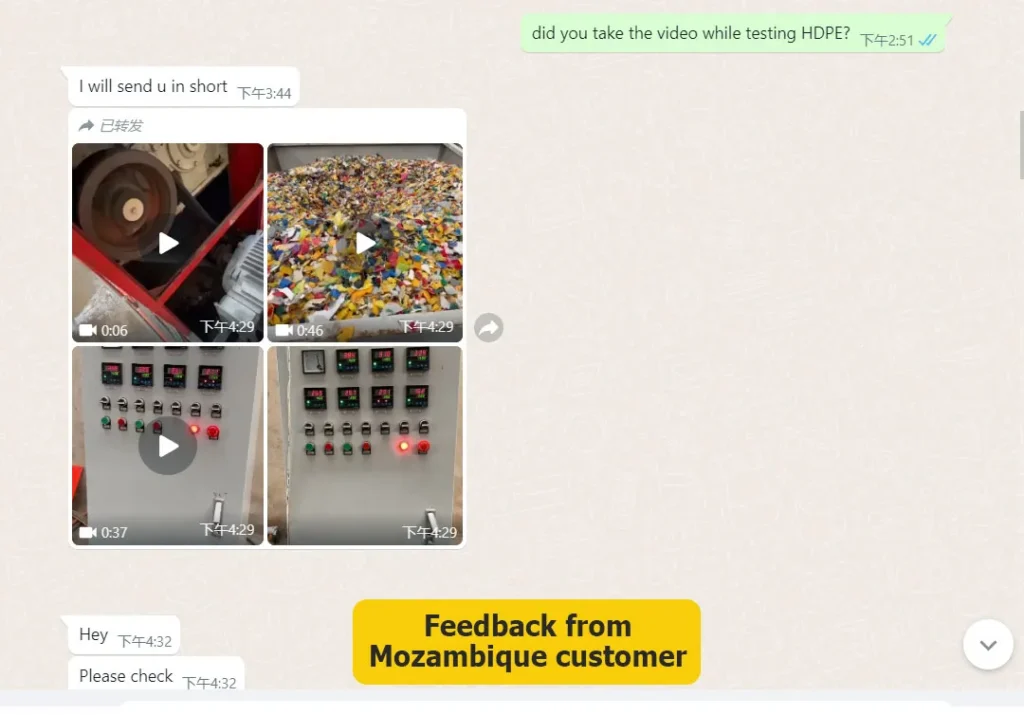

We support online or offline on-site installation, provide after-sales document support (operation manual, maintenance manual), and provide online customer service to solve problems at any time. In addition, we also provide online training and regular telephone return visits to ensure that customers can receive timely help and support.

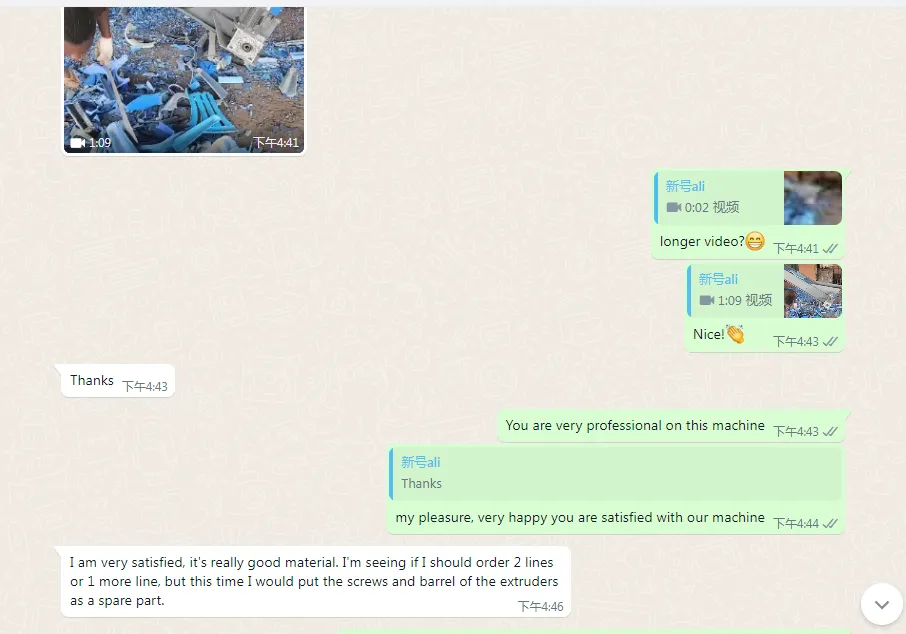

how customers say about shuliy?