Shuliy Group has provided plastic granulation production lines for more than 20 years. We can process waste plastics in PP/PE/LDPE/HDPE materials. The output of this plastic pelletizing line is 100kg to 500kg per hour. And customized capacity is available. We can provide you with not only high-quality plastic granulator machines but also integrated plastic solutions. Once you get a fully automatic plastic granulation line, you no longer need to worry about your waste plastic feeding, cleaning, crushing, granulation and storage.

Choose the right waste plastic material

Determining the waste plastic material is crucial for choosing a suitable plastic pelletizing recycling machine. Because the melting point of various plastic products is different, the processing technology is also different. Below we list the waste plastics that the Shuliy plastic granulator line can handle. If there is just the waste plastic material you want to process, please tell us your specific raw materials when you contact us so that we can make a free quotation for you as soon as possible.

Note: If you want to process PET waste plastic, please contact us to inquire Shuliy pet bottle washing line; if you want to process EPS or EPE foam, please contact us to ask about Shuliy EPS/EPE foam recycling Line.

Choose the right waste plastic material

Determining the waste plastic material is crucial for choosing a suitable plastic pelletizing recycling machine. Because the melting point of various plastic products is different, the processing technology is also different. Below we list the waste plastics that the Shuliy plastic granulator line can handle. If there is just the waste plastic material you want to process, please tell us your specific raw materials when you contact us so that we can make a free quotation for you as soon as possible.

Note: If you want to process PET waste plastic, please contact us to inquire Shuliy pet bottle washing line; if you want to process EPS or EPE foam, please contact us to ask about Shuliy EPS/EPE foam recycling Line.

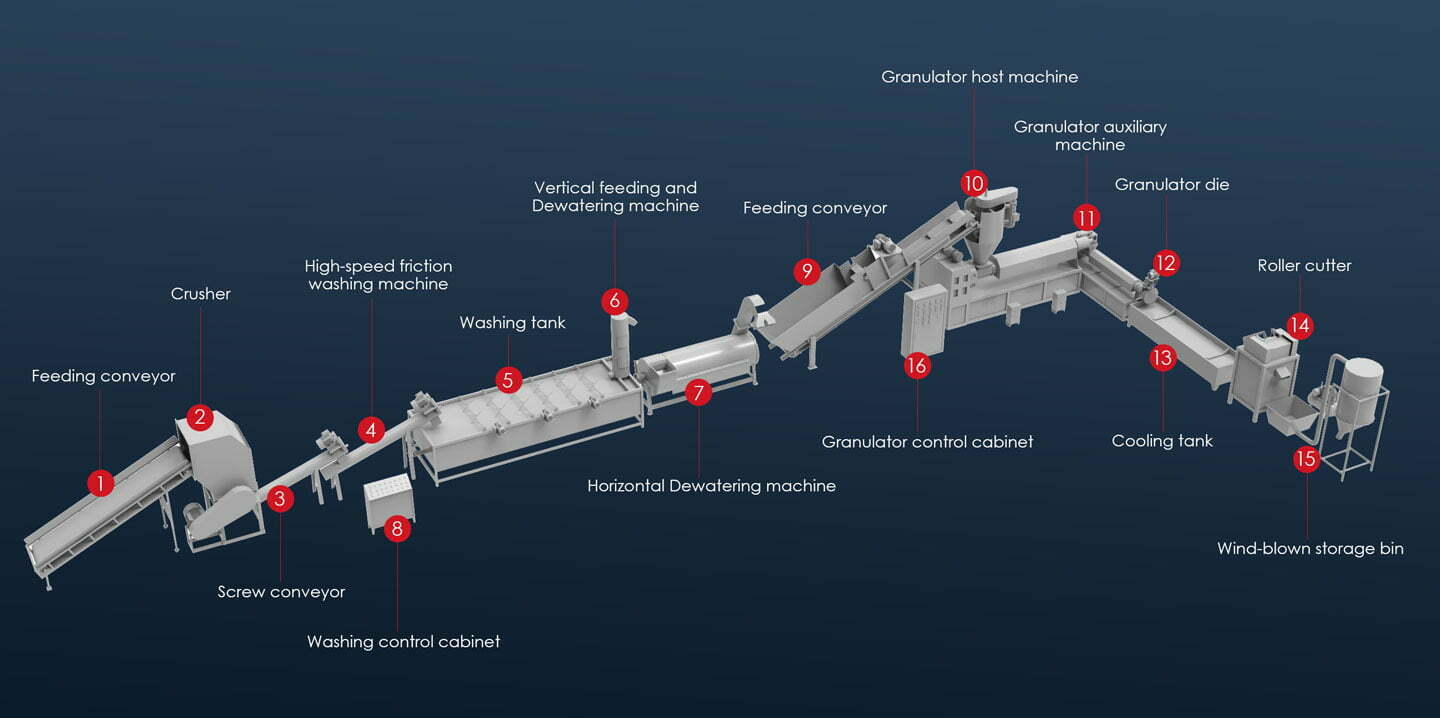

Understand Production process & Components

Features:

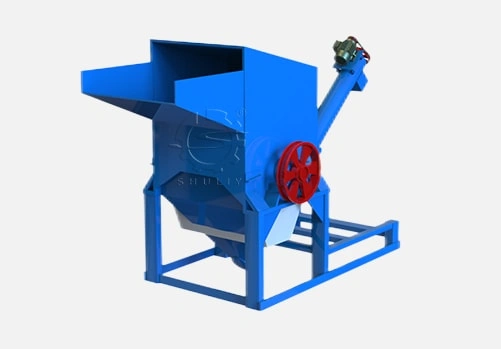

- Wet pulverization enhances the cleaning effect of waste plastics

- The blade is an alloy steel blade that can be re-sharpened for durability.

- Sealed design, the casing body is all welded with thick steel plates.

- The body adopts a separate design, which is easy to repair and clean;

- Double-layer structure, equipped with sound insulation materials, the noise is very low;

- The drive equipment adopts the medium-speed motor, low speed, and low energy consumption;

- The motor is equipped with an overload protection device and a power supply chain protection system;

Features:

- Secondary cleaning of waste plastics to achieve the highest cleanliness

- Gear mixer makes the plastic material cleaner

- The bottom is equipped with a screw-pushing device, which can automatically discharge sewage

Features:

- After rinsing, waste plastic is automatically conveyed, replacing manual feeding, saving labor and power consumption

- Automatic high-speed cleaning and dehydration, dewatering rate of more than 97%, low power consumption, high efficiency

Features:

- The extruded plastic particles are uniform, beautiful and transparent

- Adopt automatic temperature control, electromagnetic heating, less electricity consumption, no pollution, high degree of automation

- The special design of the exhaust port can effectively remove the moisture and volatile gas generated during the material melting process

- Adopt advanced low-noise hard tooth surface belt forced lubrication reducer to ensure that the main engine adapts to high-speed continuous operation

Features:

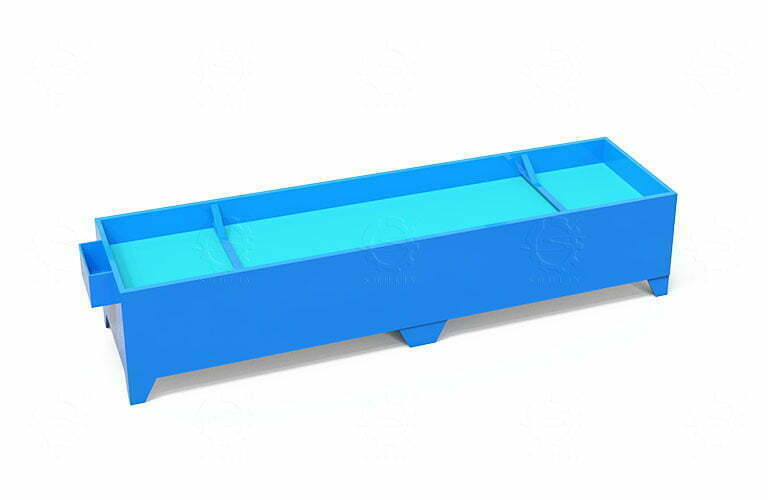

- Cool the soft plastic strip extruded from the plastic granulator to make it hard, and then it can be cut into granules

- Made of stainless steel, it can ensure no rust and corrosion when in contact with water for a long time

Features:

- The whole machine has good sealing performance, less leakage and convenient adjustment of cutting distance

- The hob is made of carbide with high wear resistance

- The whole machine is designed without gears, which can effectively reduce the noise of the machine

- The Independent electric box is convenient, safe, and beautiful

Features:

- Made of stainless steel, the storage tank and the wind-blown bin are combined into one, occupying less space and saving labor.

- The size of the storage tank can be customized according to customer requirements

- Can be connected with various granulators, easy to move

- Small fan power, fast feeding speed, cost-saving

- Hopper can be disassembled for easy cleaning

Global Cases Display

Shuliy Group specializes in the development and manufacture of plastic granulators. Our equipment has been successfully exported to more than 60 countries such as Srilanka, Nigeria, German, Congo, Kenya, Romania, Ghana, etc. All plastic granulation equipment installed so far is operating well. Through after-sales tracking feedback, we learned that customers have gained huge benefits from their plastic projects.

Shuliy Plastic Pellet Making Machine In Saudi Arabian | Good Feedback

https://www.youtube.com/watch?v=WONU0RWFqg8 Last year, our Saudi Arabian customer purchased the Shuliy Plastic Pellet Making Machine. At…

Kenyan Customer Purchases Shuliy Plastic Pelletizer For The Second Time

Good news! Our regular Kenyan customer has once again purchased a whole line of plastic…

Plastic Recycle Machines Shipped To Ethiopia

Global Cases Display

Shuliy Group specializes in the development and manufacture of plastic granulators. Our equipment has been successfully exported to more than 60 countries such as Srilanka, Nigeria, German, Congo, Kenya, Romania, Ghana, etc. All plastic granulation equipment installed so far is operating well. Through after-sales tracking feedback, we learned that customers have gained huge benefits from their plastic projects.

Reliable

- ISO and CE certification

- factory direct sales, no middlemen, affordable price

- Components are made of high-quality and durable materials, with a long service life

- Strict quality inspection system, meets factory inspection standards

Experienced Manafacture

Sincere Services

- Systematic service: machine debugging, installation, staff operation training, etc.

- More than 60 after-sales engineers, 1-year free after-sales service

- 24/7 online technical support. Our sales manager contacts customers in a timely manner and proposes professional business plans

FAQ Of Shuliy Plastic Granulation Line

Q: How much profit is there when processing one ton of PP/PE?

A: According to the Chinese profit, the profit you can get from processing one ton of raw materials is around 250USD.

Q: How many workers are needed for the whole line?

A: 3-4 people

Q: How to make particles of different colors? Is there a recipe?

A: You can add pigments during granulation, and the formula can be provided after the order is placed.

Q: My raw materials are PP, PE, PET, PVC, PS, and other different plastic products. Can it be pelletized with the same production line?

A: No, different raw materials have different processing techniques. (Example: each raw material has a different melting point)

Q: If the raw material is PP or PE, what temperature should be reached during granulation? What is the maximum temperature the machine can reach?

A: The temperature of PP/PE granulation can be 240 degrees, and the maximum working temperature of the machine can reach 500 degrees.

Q: What is the power consumption of the whole line machine?

A: To process one ton of material, the power consumption is about 500 degrees.

Q: What is the material of the granulator screw?

A: 40 Cr