Pet Bottle Washing Plant For Sale Nigeria

Brand: Shuliy

Factory History: 12 years

Exporting countries: 60+

Function: crushing PET plastic bottles into pet flakes and washing

Common Raw Materials: various PET (polyester) plastics such as water bottles, cola bottles, PET plastic bottles, etc. ;

Capacity: 500kg to 3000kg per hour (customized capacity available)

Choose Reliable pet bottle washing line Manufacturers For Nigerian

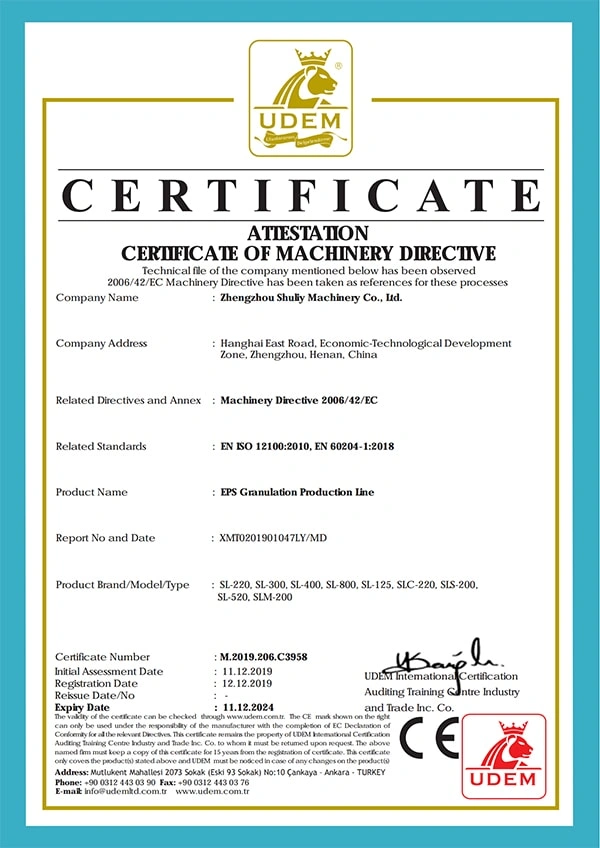

Factory And Certificate Show

240+Global Cases Show

What quality PET Flakes will you get?

Our PET washing lines produce clean, contamination-free high-quality PET flakes. The following are typical benchmarks for PET flakes produced by this recycling line:

Moisture: < 1-2%

Bulk density: < 0.3G/CM3

Total impurities: < 320ppm

PVC content: < 100ppm

Metal content: < 20ppm

PE/PP content: < 200ppm

Particle size: < 14-16mm

What is the production process of Pet Bottle Washing Plant Sale in Nigeria?

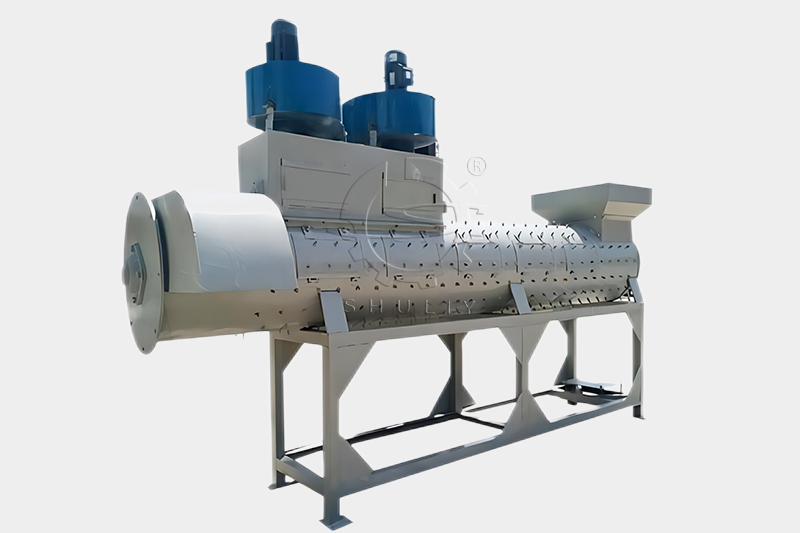

PET Bottle Label Removing Machine

The off-standard rate is 98-99% (round bottle), and the off-standard rate of the compressed bottles reaches 85-90%;

Usually, the material of the knife is an alloy knife, but the material of the 2-ton machine knife is corundum, which is wear-resistant and has a low loss;

Rinsing Tank

Secondary cleaning of waste plastics to achieve the highest cleanliness;

Gear mixer makes the plastic material cleaner;

The bottom is equipped with a screw-pushing device, which can automatically discharge sewage;

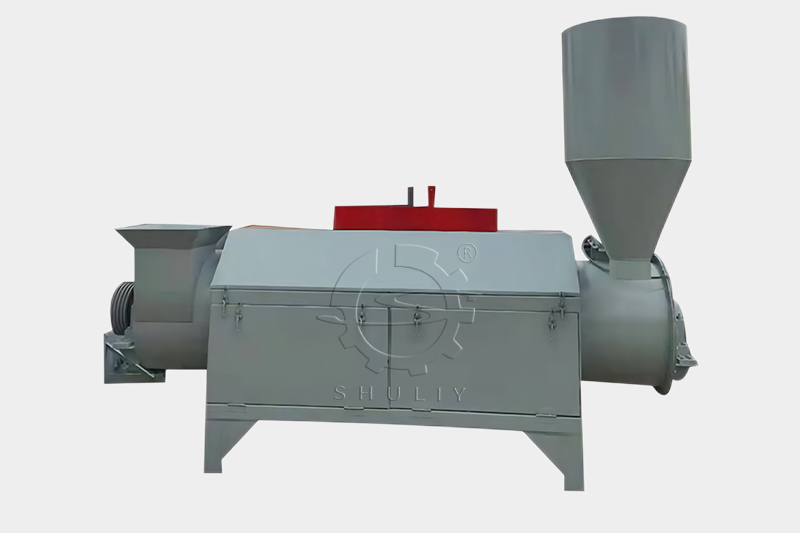

PET Plastic Crusher

Our plastic shredder cuts PET bottles into small flakes of 14-18mm size. It can be customized based on your needs. As water is continuously sprayed into the cutting chamber, the material is pre-treated and partially cleaned by this wet cutting process before being transferred to the next piece of equipment.

Hot Water Washing Machine

Clean the plastic pieces through the cleaning tank, and at the same time separate the PP or PE cap from the PET sheet;

Wash the plastic flakes with hot water. The hot water wash tank dissolves glue and leftover beverage/food items that are difficult to remove during the cold wash process. The resulting hot-washed PET flakes will be of higher value. Adding detergent may get a better cleaning effect during this period. The Shuliy hot water washing tank is an open-top structure, with functions such as automatic temperature control, heat preservation, and stirring. It also has the advantages of fast heat transfer, large temperature difference, and convenient cleaning. It is especially suitable for small, medium, and large-scale cleaning chemical fiber plants;

Fully rub the PET flakes. High-speed friction washers remove any hard-to-remove dirt and debris from PET flakes and rinse with clean water;

Wash the PET flakes again through the cleaning tank to obtain first-class cleanliness PET flakes;

Dewatering Machine

Remove any residual moisture by spinning at high speed;

The machine can automatically feed and discharge materials without manual operation, which greatly improves work efficiency;

What are the advantages of pet bottle recycling machine Sale Nigeria?

Efficient

The PET flakes making machine can process PET flakes into flakes quickly and efficiently, thus increasing production efficiency

High reliability

PET flakes making machine is reasonably designed, has a long service life and can run continuously and stably

High degree of automation

PET flakes making machine can realize automatic operation, reduce manual intervention, improve production efficiency and product quality.

Wide range of applications

PET flakes making machine can process different types of PET flakes, suitable for different production needs

What kind of services does Shuliy Group provide?

One-stop customized service

We can customize production plans and production lines, and issue layout drawings according to customer needs to ensure that customers can get satisfactory solutions.

One-to-one service

We are customer-centric, responsible for the whole process, and update the production and delivery progress for customers at any time to meet customer needs.

After-sale guarantee

We support online or offline on-site installation, provide after-sales document support (operation manual, maintenance manual), and provide online customer service to solve problems at any time. In addition, we also provide online training and regular telephone return visits to ensure that customers can receive timely help and support.