What Is Egg Tray Dryer?

An egg tray dryer is a machine used in the egg packaging industry to remove moisture from newly formed egg trays, making them strong and ready for use. These dryers use heat from various fuel sources, such as coal, natural gas, or electricity, to dry the trays before they are packed or shipped, preventing breakage and spoilage. They can range from simple, single-chamber metal boxes to large, multi-layer metal drying lines or brick-and-mortar drying rooms.

As we all know, the paper egg tray manufacturing process includes four steps: paper pulping, egg tray molding, egg tray drying, and egg tray packaging. The egg tray dryer is the main equipment in the egg tray drying process. It is usually set behind the egg tray making machine in egg tray production lines. It largely determines the automation degree of the whole production line.

Do you want to know more details about the egg tray manufacturing process? >>>

Hot-sale Egg Tray Drying Systems

According to the output of egg tray production lines and the specific needs of customers, SHULIYGROUP offers four egg tray drying systems: natural drying system, brick kiln drying system, box-type drying system, and automatic metal drying system.

Natural Drying

Natural air drying involves placing the shaped egg trays on trays (made of bamboo or galvanized steel), then on drying racks, and finally pushing them onto open ground. The process of drying by sunlight and natural wind is called air drying. Generally, 100-200 racks are needed, with 24-30 mesh sheets on each rack. Each mesh sheet can hold 3-4 egg trays.

Drying Temperature & Time: 6 hours at 30℃ and 4 hours at 35-40℃

Applicable Egg Tray Production Lines: manual egg tray production line (1000-2500pcs/h)

Advantages:No fuel and energy consumption.Low investment cost and low risk.No need to install equipment.

Disdvantages:High demand for labor force.Large area required for the drying site.Easily affected by the local weather, wind, and moisture

Brick Kiln Drying

Brick kiln drying involves constructing a closed brick chamber using red bricks, cement, and refractory materials. Molded egg trays are then fed into the drying tunnel via a mesh conveyor belt, where they dry for 15 minutes (180-200 degrees Celsius) before exiting from the other side. The drying length is typically 40-70 meters. Fuel options generally include coal, wood, natural gas, and diesel oil.

Fuel Types: natural gas, diesel, coal, wood, LPG, and so on

Height & Length: single layer with no more than 70m long (customizable)

Applicable Egg Tray Production Lines: semi-automatic egg tray production line, fully automatic egg tray production line (1000-7000pcs/h)

Advantages: Lower construction cost compared to multi-story drying systems; automation is also possible.Cost-effective and easy maintenance.Good drying effect with less labor force.Not affected by the weather and moisture.High degree of automation and high efficiency

Disadvantages: Larger footprint; higher drying costs.

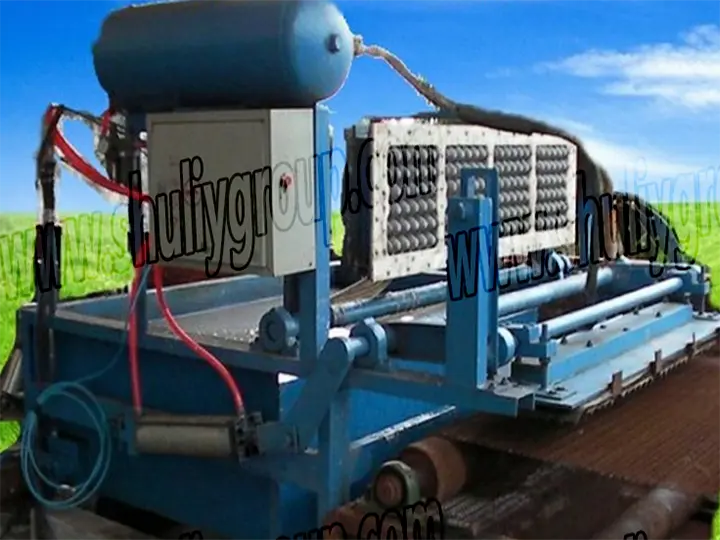

Automatic Multi-layer Metal Drying

Automated metal drying refers to the use of a fully automated metal structure drying system to guide shaped egg trays into a drying chamber. After 25 minutes of drying at 180-200 degrees Celsius across six layers, the trays exit from the bottom. The drying chamber is 18 meters long with six layers. Fuel options typically include coal, wood, natural gas, and diesel to remove residual moisture from the semi-wet egg trays. The system incorporates a belt conveyor and a PLC control system, enabling unattended drying. Currently, due to its extremely high efficiency and large output, this type of drying system is very popular with customers!

Multilayer Metal Drying System: It can be designed with 2-6 layers. Even with the egg tray machine, the occupation space is very small, which is suitable for large-scale and automatic production.

Drying Temperature & Time: 180-280℃ with 15-25 minutes.

Fuel Types: coal, wood, natural gas, and diesel, LNG, LPG, and so on.

Height & Length: single layer with no more than 70m long, 2-6 layers with about 4-5m high and 25m long.

Applicable Egg Tray Production Lines: fully automatic egg tray production line (1000-7000pcs/h).

Advantages:Almost no worker needs.Not affected by the weather and moisture.Easy installation, maintenance, and operation.Low energy consumption, reduced by about 30%.Nice appearance, large output, fully automatic, and ultra-high efficiency.

Disadvantages:Relatively high investment cost.

Box-type Drying

Box-type drying refers to dewatering the wet egg trays with a metal-structured dryer. The box-type dryer’s appearance is similar to that of the automatic metal drying system, and the drying process can be fully automated. The only difference is that it requires manual placement of egg trays onto the multi-layer drying rack before pushing them into the drying chamber. Therefore, the box-type egg tray dryer is a semi-automatic drying device suitable for small-scale egg tray production lines.

Place the formed egg tray on the tray (galvanized) and then on the drying rack, push it into the drying box, and dry it after half an hour of baking. There are 10-12 carts in the box, each of which can hold 90-100 egg trays, and 10 more carts are provided for easy recycling.

Drying Temperature & Time: 180-280℃ with 15-25 minutes.

Fuel Types: coal, diesel, natural gas, and liquefied petroleum gas.

Height & Length: customizable.

Applicable Egg Tray Production Lines: manual egg tray production line (1000-2500pcs/h).

Advantages: Production can continue in windy and rainy weather, and it occupies a small area

Egg Related Machines