Plastic Waste Recycling is becoming more and more important in today’s world. A plastic granulator is one of the most essential machines in the recycling industry, helping to convert plastic scrap into reusable granules. But many people still wonder: how does a plastic granulator work? This article explains the working principle, main components, and benefits of using a plastic granulator for recycling.

What is a Plastic Granulator?

A Plastic Granulator is a machine designed to break down waste plastic materials into small, uniform granules or flakes. Unlike a shredder, which only tears plastic into irregular pieces, a granulator cuts and grinds the material into consistent sizes that can be reused directly in the production of new plastic products.

These granules are often used as raw material for manufacturing pipes, bottles, films, packaging materials, and other plastic items.

How Does a Plastic Granulator Work?

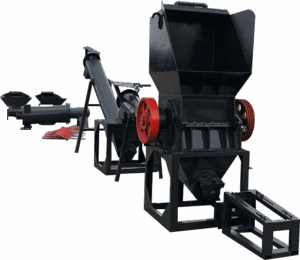

Crusher

Crusher Machine can crush all kinds of waste plastic plastic products. The pellets can be directly extruded by a pelletizer as a raw material for production. This equipment adopts alloy steel blade, which has a long service life. At the same time, the machine adopts a separate design, which is easy to repair and clean, and has a double-layer structure. It is equipped with sound insulation materials, and the noise is very low. , so that the bearing rotates well for a long time. The drive equipment adopts a medium-speed motor, with low noise and low energy consumption. The motor is equipped with an overload protection device and a power supply chain protection system.

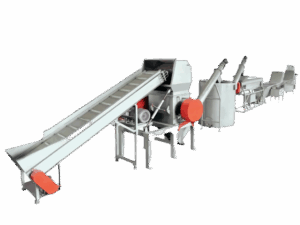

Granulator Machine

Two-stage tandem exhaust granulation unit is widely used in the recycling and granulation of various types of plastics such as (LDPE), (HDPE),(PET), (PP). The specially designed exhaust port can effectively remove the moisture and volatile gas generated during the melting process of the material, and the extruded particles are uniform, beautiful, and transparent, and the production efficiency is high. The main engine adapts to high-speed continuous operation.

Roller Cutter

It is suitable for pelletizing after pelletizing, uniform, simple, durable, cost-effective, easy to change the knife and easy to operate.

Applications of Plastic Granulators

plastic granulator machine is mainly used for processing waste plastic films (industrial packaging films, agricultural plastic films, greenhouse films, handbags, etc.), woven bags, agricultural convenience bags, pots, barrels, beverage bottles, furniture, daily necessities, etc., suitable for most common waste Plastic, which is a plastic recycling processing machine that is widely used in the waste plastic recycling industry and its granulation process is also popular for users.

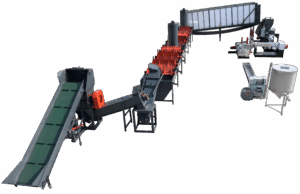

We have corresponding production lines for different raw materials. If you have any special materials, please feel free to contact us and our sales manager will give you better suggestions.

PET bottle recycling

HDPE and LDPE film recycling

PP and PE rigid plastic recycling

Plastic Pelletizer Machine

EPS / EPE Foam Granulating Line