Egg Tray Machine (Pulp Tray Forming Machine) For Sale

Brand: Shuliy/Egg Tray Machine

Factory History: 12 years

Exporting countries: 60+

Function: automatically produce large quantities of high quality egg trays from waste paper in a short period of time;

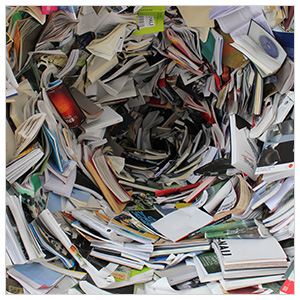

Common Raw Materials: waste paper boxes, waste books, waste newspapers, waste cartons, book scraps, recycled egg trays and used egg trays, and other waste paper materials;

Output capacity: 1000pieces to 7000pieces per hour (customized capacity available)

Drying System: natural, brick, and metal drying

Machine Color & Final Egg Tray Color: customized available

Parameters of Egg Tray Machine

We can provide customized solutions according to your requirements. If you need an egg tray production line with a larger output, you can contact us.

| Model | SL-1500 – 3*1 | SL-2500 – 3*4 | SL-3000 – 4*4 | SL-4000 – 4*8 | SL-5000 – 5*8 | SL-7000-6*8 |

|---|---|---|---|---|---|---|

| Capacity/h | 1500p | 2500p | 3000p | 4000p | 5000p | 7000p |

| Power/h | 38kw | 55kw | 60kw | 95kw | 95kw | 120kw |

| power supply | 380V50HZ | 380V50HZ | 380V50HZ | 380V50HZ | 380V50HZ | 380V50HZ |

| weight | 3000kg | 4000kg | 4800kg | 7000kg | 8000kg | 10000kg |

| Dimensions (host) | 2800*2200*1900 | 2900*1800*1800 | 3250*1800*1800 | 3250*2300*2500 | 37000*2300*2500 | 3200*2300*2500 |

| Paper consumption/h | 120kg | 200kg | 240kg | 320kg | 400kg | 480kg |

| Water consumption/h | 240kg | 400kg | 480kg | 640kg | 800kg | 960kg |

| dryer | airing/drying box | airing / drying room | brick/metal drying | brick/metal drying | brick/metal drying | brick/metal drying |

The egg tray machine is also a type of pulp forming machine. It is mainly used to produce egg trays. By changing the mold,By changing the mold, it can also be used to produce egg boxes, fruit trays, coffee cup trays, seedling trays, shoe trays and other pulp trays.

The egg tray machine can process waste paper boxes, waste books, waste newspapers, waste cartons, book scraps, recycled egg trays and used egg trays, and other waste paper materials into pulp, mold it, and dry it into paper trays of different sizes and shapes.

Model:

SL-1500 – 3*1, SL-2500 – 3*4, SL-3000 – 4*4, SL-4000 – 4*8, SL-5000 – 5*8, SL-7000 – 6*8, Larger output can be customized.

Shuliygroup’s egg tray machines are cost-effective, long-lasting and come in a full range of models. Customized egg tray production solutions can also be designed according to customer specific needs.

SL6*8-7000 Piece

Model: WJ-7000-6X8

Output: 7000 pcs/h

Power: 120w

dryer: brick/metal drying

Customization Service: support

SL5*8-5000 Piece

Model: WJ-5000 – 5X8

Output: 5000 pcs/h

Power: 95kw

dryer: brick/metal drying

Customization Service: support

Egg Tray Machine Processing Process

Egg Tray Raw Materials

Raw material types may affects the quality of the final paper tray products. For example, using waste paper with a high ink content may result in a poor egg tray appearance, while using low-quality paper may result in an egg tray that is weak and easily deformed. Therefore, to produce high-quality egg trays, you can send your waste paper picture to our sales manager, and we will tell you what kind of paper tray you may get in the end.

Molded Paper Trays

egg tray drying systems

Natural Drying Systems

Compatible machine: small egg tray machine

Suitable output: less than 2000 pieces

Site requirements: large and ventilated

Suitable country: high temperature all year round

Drying effect: simple

Natural Drying Systems

Drying type: ①semi-automatic trolley drying; ②automatic conveying drying

Suitable output: less than 1500 pieces (semi-automatic); more than 2000 pieces (automatic)

Site requirements: large area, civil engineering is required

Drying advantage: not affected by the weather

Drying effect: better than natural air drying

Metal Drying Systems

Site requirements: small footprint

Aesthetic effect: the appearance is more beautiful and clean

Installation situation: easy to install

Drying advantage: not affected by the weather

Drying effect: fast, it only takes about 25 minutes from wet to dry

Customized situation: single-layer or double-layer conveyor belt can be selected

Waste Paper Pulping

- Process: Waste paper and water (1:10 ratio) will be made into rough pulp through hydraulic pulper, and then put into the homogenization pool (pigments, waterproof glue, etc. are added to this tank). Then water and paper pulp enters into supply plup through pulp pump, so that the concentration in the pulp supply tank reaches 3%-5%.

- Advantages: High pulping efficiency: pulping machine can quickly make raw materials such as waste paper and pulp into slurry suitable for egg tray production, which improves the pulping efficiency.

Paper Tray Forming

- Process: Ads the pulp on the mold through the negative pressure of the vacuum pump, and then dehydrate and form. Then use the positive pressure of the air compressor to make the already forming paper tray, blow to the transfer mold, and then blow the paper tray on the transfer mold through the positive pressure to the tray, or the mesh belt

- Advantages: Our molding system features automatic mold transfer, high precision, consistency, and adjustable speed.

Formed Tray Drying

- Drying Method: Natural drying, brick drying or metal drying

- Advantages: Dryer is used to remove moisture from molded egg trays. shuliy drying system features high efficiency, low energy consumption, and adjustable temperature and humidity settings to ensure proper drying of egg trays.

Hot Pressing And Stacking

- Process: Pressed egg trays are hot pressed through a hot press, then counted and stacked and packed through a stacking machine

- Advantages: Hot pressing makes the egg trays stronger and less deformable, improving product quality. Stacking can make the egg trays batch process and improve the production efficiency.

- Note: All final products except egg trays should preferably be hot pressed using a hot press

Why Choose Shuliy for Your Pulp molding machines Needs?

One-stop customized service

We can customize production plans and production lines, and issue layout drawings according to customer needs to ensure that customers can get satisfactory solutions.

One-to-one service

We are customer-centric, responsible for the whole process, and update the production and delivery progress for customers at any time to meet customer needs.

After-sale guarantee

We support online or offline on-site installation, provide after-sales document support (operation manual, maintenance manual), and provide online customer service to solve problems at any time. In addition, we also provide online training and regular telephone return visits to ensure that customers can receive timely help and support.

Choose Reliable pulp molding machine manufacturers

Other Cases Show

Egg Related Machines