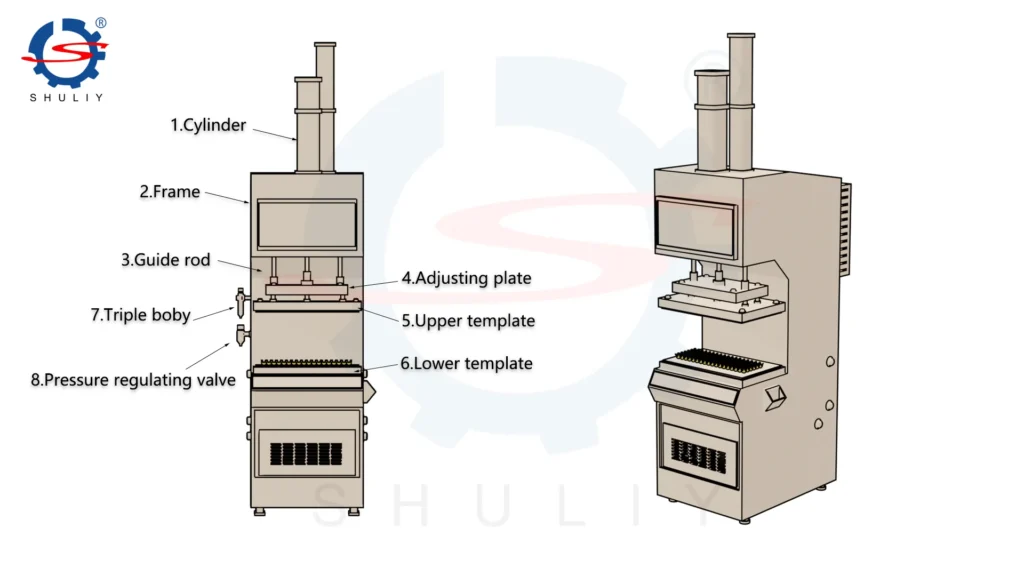

Hot Pressing Machine Introduction

HOT PRESSING MACHINE Used to make end product more flat and smooth Die temperature:120-200°C

Heat treated pallets: Paper pulp moulding hot pressing shaping machine designed and manufactured SLy our own professional engineers is a kind of equipment used to shape the drying paper tray products under high temperature and high pressure, After processed SLy the machine, the paper tray products are provided with fine anti-shocking performance and delicate appearance.

Hot Pressing Machine

Technical Parameters

Model:SL-15

Power:6.5kw

Size:1200*800*1800mm

Weight:1.5tons

Band:Shuliy

Hot Press Machine Mold Principle

The Open hot press mold customization mainly includes four system:

1.Sending design 3D drawings or samples

2.Select material

3.Open molds

4.Forming molds

Open mold customization, carefully selected materials, acid and alkali resistance, not easy to deform, stable and strong, complete specifications, source manufacturers, perfect after-sales.

1.It is processed by high-quality aluminum , with good extrusion performance, good strength, light weight, and corrosion resistance

2.The surface of the mold is fine and smooth, the color is bright, the hand feel is smooth and comfortable, the lines are smooth, and the craftsmanship is skillful.

3.The appearance is beautiful, the aluminum alloy is processed at one time, the whole is flawless, and the produced product is beautiful.

4.Recycling, can be used many times, stable performance, long service life, not easy to deform

5.Drawings and samples, support customized processing, many years of experience in mold opening customization, accurate mold opening.

Other Auxiliary Equipments

Egg Related Machines