Introduction To Charcoal Making Machine

Charcoal Making Machine is specially designed for biomass waste recycling. The raw materials are agricultural waste, forestry waste, and organic food waste, such as branches, straw, straw, peanut shells, tree trunks, cotton stalks, tea seed shells, fruit shells, weeds, Leaves and other raw materials containing biomass fibers that can be used to make charcoal are filled and crushed into charcoal.

Charcoal is passed through a grinder. Put the powder within 10mm into a dryer to dry it so that the moisture content is within 12%. Put it into a rod making machine and form it under high temperature and high pressure (without adding any additives), and then put it into a carbonization furnace for carbonization. Finished machine-made charcoal. A continuous carbonization furnace can also be used to directly carbonize the raw material powder into carbon powder at high temperature.

During the carbonization process (also called pyrolysis process), waste can be converted into charcoal, wood vinegar, tar and flammable gas. Depending on the model, the treatment efficiency of the carbonization furnace is usually between 800kg/h-3t/h, others You can leave us a message regarding your production capacity to customize your own charcoal machine solution.

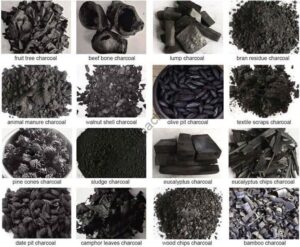

Different raw materials use different carbonization machines to produce charcoal for different uses.

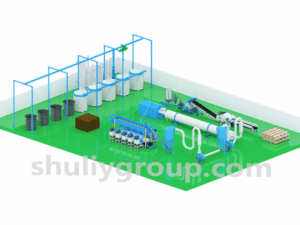

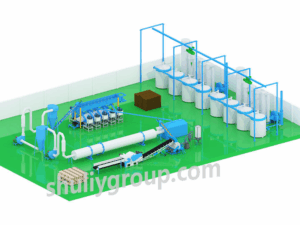

The simple fully automatic charcoal machine production line mainly includes: crusher, dryer, rod making machine, carbonization furnace, trommel screen, single screw feeder, twin screw unloader, automatic rod cutting machine, steel mesh conveyor, packaging machine and other equipment.

Leave a message telling us your raw material and production capacity requirements, and the sales manager can provide professional customized charcoal production line solutions based on your project needs.We also have Continuous Carbonization Furnace Sale,welcome to contact!

BBQ Charcoal Making Machine

A complete set of barbecue charcoal plant includes carbonization equipment, lump charcoal grinder, charcoal ball press machine, bbq charcoal briquettes dryer, and briquettes packing machine. The processing capacity can be customized between 500kg/h-30t/d. Among them, charcoal press machine is the main molding equipment, which can process spherical, oval, heart-shaped, pillow-shaped, and lettering BBQ briquettes.

Briquettes Charcoal Processing Plant

The industrial honeycomb coal briquette production line is a series of equipment for deep processing coal powder and charcoal powder, mainly crushers, mixers, coal briquettes forming machines, and dryers. Through this briquettes charcoal processing plant, we can make coal powder and charcoal powder into solid briquettes of different shapes. You can use these coal or coal or charcoal briquettes for barbecues, boiler burning, restaurants, heating, and other purposes. The configuration of the honeycomb coal briquettes production line can be customized according to specific customer needs, and its output is 500kg/h to 2t/h.

Wood block production line

Wood block production line can process high-quality compressed sawdust blocks for wood pallets processing. The production process of the compressed wood block production line mainly includes wood crushing, sawdust drying, sawdust mixing, wood block extrusion molding, wood block cutting, etc.Using sawdust block machines, we can recycle a large amount of sawdust, wood shavings, and various biomass raw materials to produce high-value-added wooden blocks. At present, many foreign customers have ordered our full set of wood block making machines to carry out pallets processing business, such as the United States, Mexico, Argentina, Malaysia, New Zealand, Ghana, South Africa, Iran, Saudi Arabia, Romania, Germany, Belgium, Finland, Russia, etc.

Barbecue charcoal production line

The barbecue charcoal production line mainly processes various types of charcoal balls. The BBQ charcoal briquettes processing plant can produce barbecue charcoal of various specifications and sizes. The industry’s barbecue charcoal production line is an automated BBQ briquettes processing line independently designed by the Shuliy factory.The production line mainly includes a continuous carbonization furnace, automatic conveyor, carbon crusher, screw conveyor, storage bin, screw conveyor, carbon powder crusher and mixer, binder mixer, continuous conveyor, BBQ charcoal briquettes press machine, briquettes dryer machine, and barbecue charcoal packaging machine.

Final Product Display