Model: TZ-55-52/Silage Baler

Power: 5.5+1.1kw, 3 phase.

Size: 2135*1350*1300mm.

Bale size: Φ550*520mm.

Machine weight: 850kg

Diesel engine: 15 hp

Baling speed: 50-60 piece/h, 5-6t/h.

Bale weight: 65-100kg/bale.

Bale density: 450-500kg/m³

Rope consumption: 2.5kg/t

Wrapping machine power: 1.1-3kw, 3 phase

Film wrapping speed: 13s for 2-layer film,19s for 3-layer film

Warranty: 1 year.

Advantage:Chinese factory, 30 year R&D experience,14 years of export experience,high cost performance, fast delivery.Leading technology.Quality assurance.Good reputation

Service: Free customized solution. Installation and debugging. Free training operation. lifelong online technical support. provide installation video,operation instruction. Welcome to visit our factory.

The silage baler can bale and wrap crop stalks and silage feed after they have been chopped by a shredder or silage harvester.

The final bale size is 550*520mm standard bale formation + fully automatic wrapping, with a production efficiency of 60-65 bales/hour. Each bale weighs approximately 65-100 kg, or 5-6 tons/hour, depending on the moisture content of the silage.

Baling and wrapping silage significantly reduces feed transportation and storage costs. With a density of 450-500 kg/m³, it can efficiently compress materials such as corn stalks, alfalfa, and sugarcane leaves. This machine can reduce storage space by 40%-60%, reduce labor, and extend the feeding time of silage.

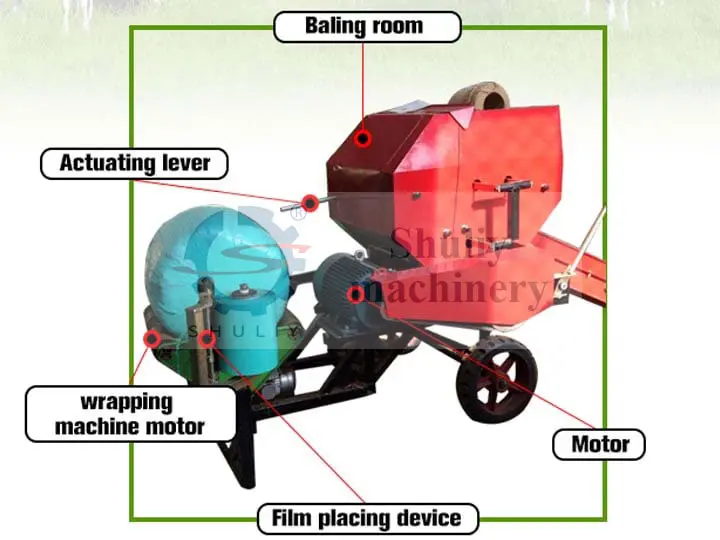

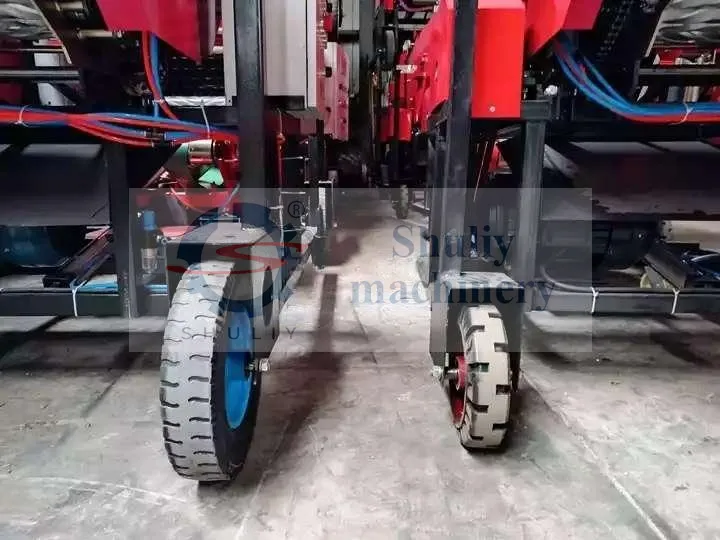

The silage baler is available in electric and diesel-powered versions to suit various working environments. Its main components include a conveyor belt, baling chamber, wrapping system, and electric motor/diesel engine. You can choose the appropriate power source as needed.

Using 2-6 layers of adjustable film wrapping technology, the open-air storage period of silage can be extended to 2-3 years. This improves feed quality and reduces livestock farming costs.

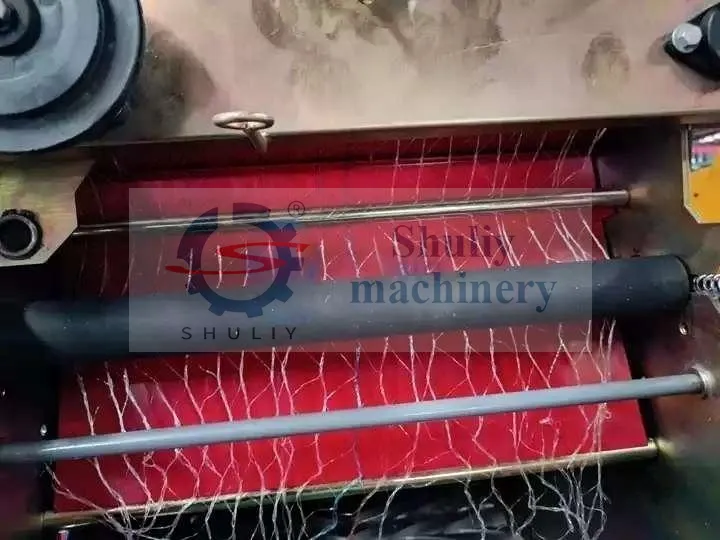

Bales are secured with twine or plastic netting, and wrapped with silage film.

After being wrapped with plastic film, the silage undergoes natural fermentation, producing beneficial bacteria, lactic acid bacteria, and proteins, which are easily absorbed by livestock such as cattle and sheep, thus improving their growth rate.If you need higher production capacity, we also have model 60 (9YDB-60) and model 70 (9YDB-70) available. Please feel free to inquire.

Structure of Mini Silage Baler for Sale

The corn silage baler machine mainly includes a conveyor belt, baling chamber, wrapping system, and motor/diesel engine. The overall structure is simple and easy to understand and operate. The silage after baling is dense and easy to store and transport.

Technical Parameters of the Silage Baler Machine

we supply diesel engines and electric motors.Firstly, you should understand which needs the power to run. For this silage baler machine, the main machine, the wrapping frame, and the air compressor need the power to support it.And then, get to know the differences between them. The diesel engine can provide power by itself. But the electric motor should get help from the electricity. So, you can choose the suitable power according to your actual demands.

| Model | TZ-55-52(with diesel engine) |

| Power | 15hp diesel engine |

| Bale size | Φ550*520mm |

| Baling speed | 50-60pcs/h, 5-6t/h |

| Machine size | 3520*1650*1650mm |

| Machine weight | 850kg |

| Bale weight | 65-100kg/bale |

| Bale density | 450-500kg/m³ |

| Film wrapping speed | 13s for 2-layer film,19s for 3-layer film |

| Model | TZ-55-52(with motor) |

| Power | 5.5+0.55kw , 3 phase |

| Bale size | Φ550*520mm |

| Baling speed | 50-60 pcs/h, 5-6t/h |

| Machine size | 3380*1370*1300mm |

| Machine weight | 456kg |

| Bale weight | 65-100kg/bale |

| Bale density | 450-500kg/m³ |

| Film wrapping speed | 13s for 2 layer film ,19s for 3 layer film |

Raw Materials/Final Products

Wrapping materials

You can use the plastic net ,film or hemp rope. 50 bundles hemp rope or plastic net can be used for 2-3 years

Working Principle of Silage Baler and Wrapper

Bundled Part

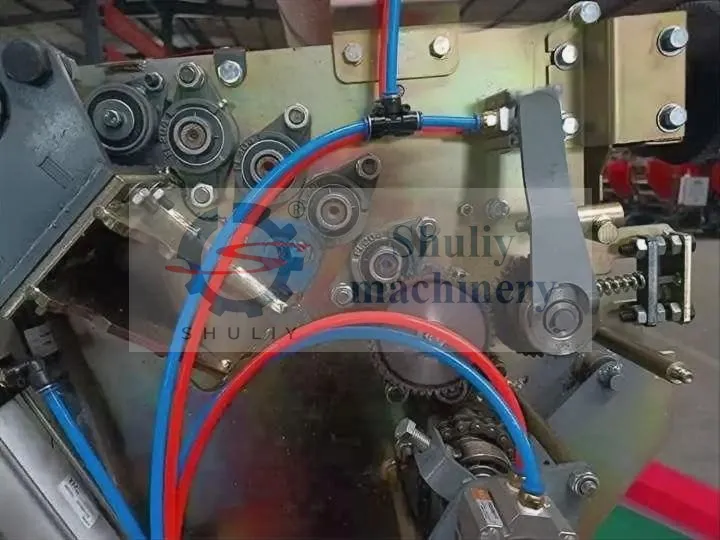

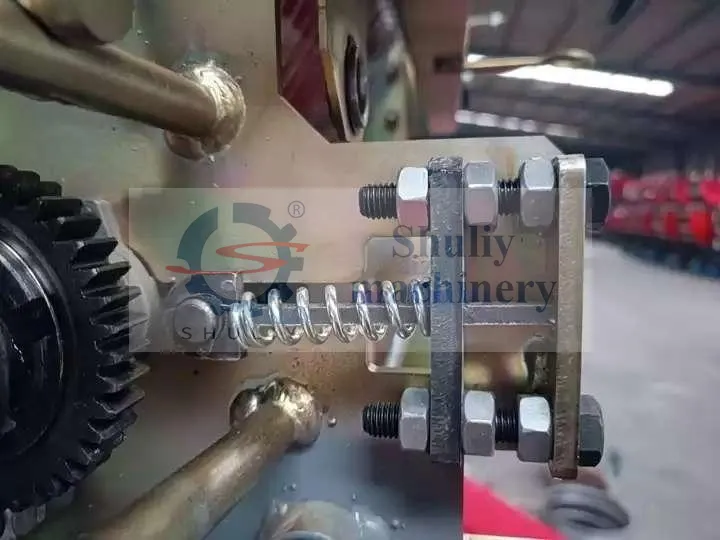

Manual feeding into the fixed bin of the machine. When the bale reaches a certain capacity of the fixed bin and the movable bin, the idle roller above the movable bin and the signal wheel on the left will rotate evenly.

Then the operator moves the winding rope clutch handle, and the hay baler machine begins to reciprocate the rope binding, winding the rope once. Finally, the rope is automatically cut, and the warehouse door is immediately opened to release the bale, and the bale falls directly onto the rotating frame of the film wrapping.

Wrap process

Pull out the membrane by hand, then start up the rotating button, next the rotating frame will drive the bale to rotate. The operator should simultaneously and quickly press the membrane to the bale, and rotate with the bale for a full circle, and then immediately let go.

Working Video of Silage Baler

The working process follows the basic steps below:

1.Raw Material Feeding

Two types are available. One is manual feeding, and another one is machine feeding automatically. The raw materials are conveyed to the destination. When the materials are sufficient, it alarms. The conveyor belt will stop.

2.Bundling

The feed will be bundled in the specified location, and the rope or plastic net will bundle the feed into a round shape.

3.Wrapping

After bundling, use wrapping films to wrap the bundled feed to store for a long period.

Global Cases