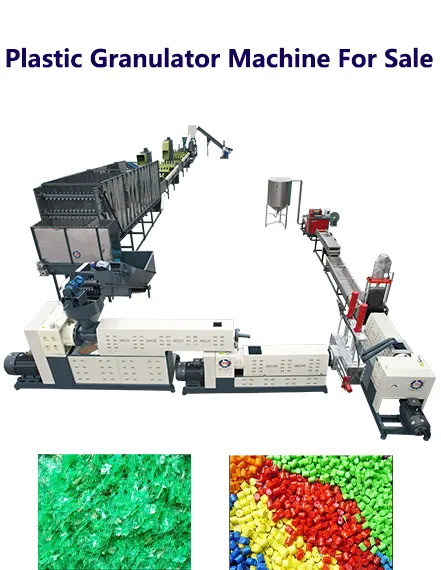

plastic Granulator Machine For Sale

Brand: Shuliy

Factory History: 15 years

Exporting countries: 60+

Function: used to remelt waste plastics, then extrude plastic strips and cut them into recycled plastic pellets. ( crushing, cleaning, melting, extrusion, and pelletizing).

Common Raw Materials: PP plastics, PE plastics, PET plastics, LDPE plastics, HDPE plastics, EPS foam, EPE foam, etc (customized capacity available) ;

Screw Diameter: 105mm-220mm

Color: customized available

Type:Different plastics use different machine configurations, and solutions can be customized based on customer raw materials.

Capacity: 100kg/h, 200kg/h, 300kg/h, 500-800kg/h,1-5t/h..

Particle Length: 4mm(conventional), can be customized.

Particle Diameter: 3mm(conventional), can be customized.

Warranty: 1 year.

Advantage:Chinese factory, 15year R&D experience, high cost performance, fast delivery.

Service: Free customized solution. Installation and debugging. Free training operation. Welcome to visit our factory.

What kind of waste plastic can be processed?

What Kind Of Plastic Pellets Will You Get?

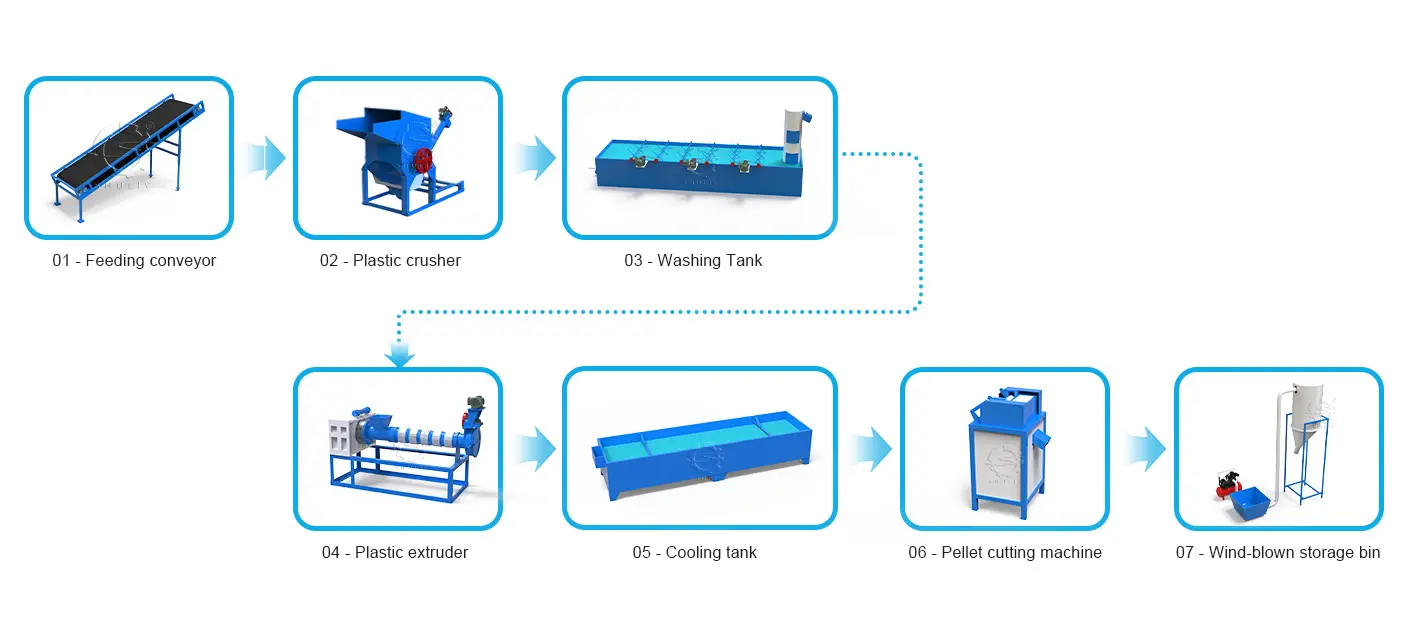

What is the production process of the plastic granulator?

It’s mainly used for processing waste plastic films (industrial packaging films, agricultural plastic films, greenhouse films, handbags, etc.), woven bags, agricultural convenience bags, pots, barrels, beverage bottles, furniture, daily necessities, etc., suitable for most common waste Plastic, which is a plastic recycling processing machine that is widely used in the waste plastic recycling industry and is more popular for users.

With special double-stage screw design and different configurations, it is suitable for the production of PET, PP, PE, PS, ABS, PA, PVC, PC, POM, EVA, LCP, PMMA and other plastic recycling granulation. The reduction box adopts the design of high torque, which realizes the performance of noiseless and smooth operation. The screw and barrel are specially hardened, which has the characteristics of wear resistance, good mixing performance and high output. The design of vacuum exhaust or ordinary exhaust port can discharge moisture and waste gas during the production process, so that the material can be discharged. It is more stable and the colloidal particles are stronger, which ensures the good quality of the product.

Principle: The process of high temperature melting, plasticization and extrusion is used to change the physical properties of plastics to achieve plasticization and molding of plastics.

The main equipment of this production line is suitable for recycled various plastics materials such as PP/PE/EPS/HDPE and so on,with an hourly output of 150kg, 200kg, 300kg, 500kg, 1000kg, 2000kg and other different outputs,which is an automatic assembly line from washing and crushing to granulation.

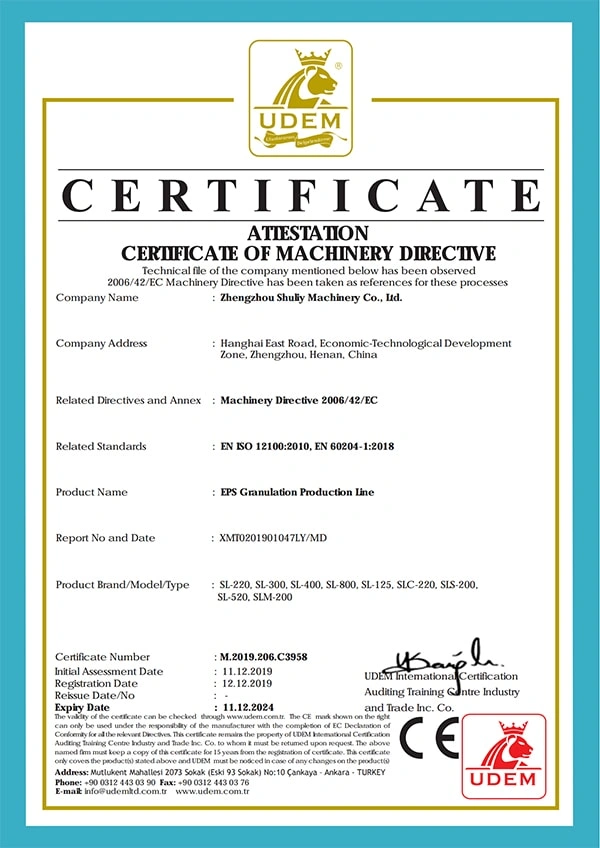

Choose Reliable Plastic Granulator Manufacturers

Factory And Certificate Show

240+Global Cases Show

What are the advantages of plastic granulator?

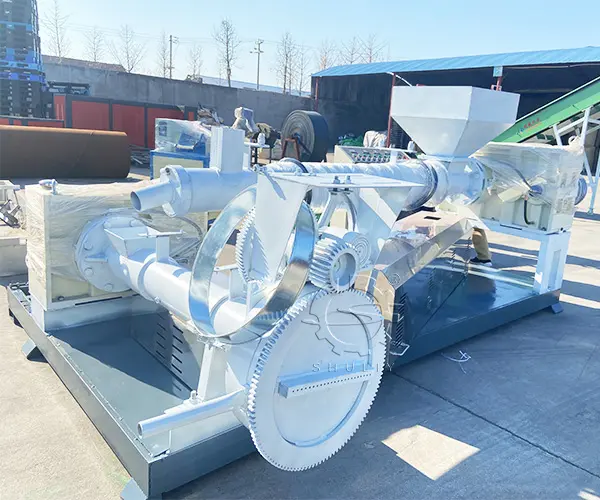

High-quality material

The screw of Shuliy plastic granulator is made of 40 CR medium carbon alloy steel material, which can maintain stability under high temperature, high pressure and high speed operation.

High work efficiency

The control cabinet is fully controlled, with a high degree of automation, simple and convenient operation, and high production efficiency, which can greatly improve production efficiency and reduce labor costs.

Long Service life

The components of the plastic granulator are made of high-quality materials, which are durable and can work stably for a long time. Our old customers have machines that have been used for more than 10 years, and they are still running well.

Easy to install

Our plastic granulator has been installed before leaving the factory and shipped as a package. Usually do not need too much commissioning and installation work, and can be put into operation quickly

High quality

Parts and components have been precision processed and high-quality testing, which can ensure the stable quality of particles and reduce the occurrence of defective products.

Energy saving

The use of high-efficiency motors and heat exchangers can minimize energy waste, improve production efficiency and reduce production costs.

Reasonable layout

The layout is reasonable, the structure is compact, and the space occupied is small, which can save the workshop space to the greatest extent.

Run smoothly

Using advanced control system, it can automatically adjust production parameters to ensure production stability and consistency.

What kind of services does Shuliy Group provide?

One-stop customized service

We can customize production plans and production lines, and issue layout drawings according to customer needs to ensure that customers can get satisfactory solutions.

One-to-one service

We are customer-centric, responsible for the whole process, and update the production and delivery progress for customers at any time to meet customer needs.

After-sale guarantee

We support online or offline on-site installation, provide after-sales document support (operation manual, maintenance manual), and provide online customer service to solve problems at any time. In addition, we also provide online training and regular telephone return visits to ensure that customers can receive timely help and support.