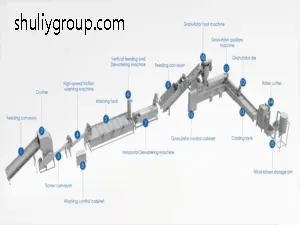

La machine de recyclage de plastique dur, également connue sous le nom de machine de recyclage de plastique rigide ou ligne de granulation de plastique dur, est une solution complète de recyclage conçue pour traiter les plastiques rigides tels que PP, PE, ABS, PC, HDPE, et PVC, etc. Ce système combine un broyeur de plastique dur, concasseur, ligne de lavage de plastique, un laveur à friction, une machine de déshydratation, et machine de pelletisation de plastique pour transformer les plastiques rigides post-consommation et industriels en pellets recyclés propres et réutilisables. Il est largement utilisé dans les usines de recyclage de plastique professionnelles nécessitant une haute production, une performance stable et un recyclage rentable.

Capacité : 100kg/h, 200kg/h, 300kg/h, 500-800kg/h.

Longueur des particules : 4mm (conventionnel), peut être personnalisé.

Diamètre des particules : 3mm (conventionnel), peut être personnalisé.

Garantie : 1 an.

Matériaux bruts : Fûts en PP et HDPE, boîtes d'emballage alimentaire en plastique, fils et câbles, matériaux de construction, pièces moulées par injection, fûts chimiques, bidons en HDPE bleus, palettes en plastique, compteurs électriques kWh, pare-chocs automobiles, plastiques techniques, portes et fenêtres en plastique, tuyaux d'égout, tuyaux de canalisation, prises électriques, boîtiers d'appareils électriques, etc.

Matériaux bruts

Produit final : Granulés de plastique

Quelle est la procédure de recyclage du plastique dur ?

Étape 1 : Lavage et broyage

Le broyage est toujours la première étape du recyclage du plastique dur. Mettez les matériaux rigides comme les contenants rigides dans un broyeur à plastique, les flocons de plastique broyés (regrinds) doivent être lavés dans un tank de lavage. Le tank de lavage peut éliminer la saleté et la graisse des flocons de plastique. Notre tank de rinçage en plastique de haute qualité, modèle SL-150, possède une longueur de tank de 15-20 m. Avec dix roues rotatives espacées de 1,5 à 2 m, ce tank assure un nettoyage et un rinçage efficaces des flocons de plastique.

Étape 2 : Séchage

Le séchage des copeaux de plastique est effectué pour que le processus de pelletisation puisse se faire avec moins de fumées et à une température garantie. Nous associons la ligne de recyclage à des sécheurs verticaux et horizontaux. Les sécheurs utilisent la force centrifuge pour éliminer l'humidité, garantissant que les plastiques recyclés ont moins de 5 % d'humidité.

Étape 3 : Pelletisation et découpe

Après séchage, la matière première sera introduite dans la pelletiseuse, où le plastique sera progressivement fondu à une température de 300 degrés Celsius. Différents matériaux nécessitent des températures de fusion légèrement différentes. La fusion du plastique est extrudée par une vis, refroidie par de l'eau froide et coupée en petits granulés par un coupeur à granulés.

Autres produits populaires liés

Ligne de recyclage de film plastique PP/PE/LDPE

Ligne de recyclage de film plastique PP/PE/LDPE Marque : ShuliyCapacité : 100kg-500kg/h, 1-5t/h.Longueur des particules : 4mm (conventionnel), peut être personnalisé.Diamètre des particules : 3mm (conventionnel), peut être personnalisé.Matériau…

machine à brasser en plastique

Paramètres techniques du broyeur en plastique Modèle SLSP-600SLSP-800SLSP-1000Puissance du moteur30 kW45 kW55 kWCapacité600-800kg/h800-1000kg/h1000-1200kg/hMatériau des lames60Si2Mn60Si2Mn60Si2MnNombre de lames10pcs10pcs10pcsLargeur de la boîte600cm800cm1000cm Obtenez…

Lignes de lavage et de pelletisation de plastique

Marque : ShuliyLigne de recyclage de film plastique PP PE : polypropylène (PP) et polyéthylène (PE). Produits plastiques jetables tels que…

Granulateur en plastique

Machine de granulation en plastique à vendre Marque : ShuliyHistoire : 15 ansPays d'exportation : 60 Fonction : utilisée pour faire fondre…